Agricultural Processing Equipments Important Point

Agricultural Processing Equipments Study Content

1.Areacanut Dehusker

| Function |

To dehusk the dried arecanut fruits |

| Specification |

Overall dimension

(L x B x H, mm)

|

1660 x 600 x 1615 |

| Capacity |

30 kg/h |

| Power required |

1 hp electric motor |

| Cost of the unit (Approximate) |

Rs.37, 500/- |

| Cost of operation |

Rs.15/h |

| General Information |

- It consists of a mainframe on which a rotary shelling drum having 8 Nos. of solid rubbers on its periphery is mounted (like rasp bar threshing cylinder).

- The husk is thrown out and the kernels / nuts are collected at the bottom.

- Grading the dried fruits before dehusking will also help to increase the dehusking efficiency and reduce the breakage.

|

| Sailent Features |

- The unit is portable.

- Depending upon the size of the fruit, the concave has to be changed.

- Initial grading of fruits will increase the dehusking efficiency.

- It is suitable for continuous dehusking.

|

|

2.Groundnut Decorticator (Power Operated)

| Function |

To shell groundnut pods and separate kernels |

| Specification |

Overall dimension

(L x B x H, mm)

|

1130 x 350 x 1345 |

| Capacity |

400 kg/h |

| Power required |

1 hp electric motor |

| Cost of the unit (Approximate) |

Rs.45,000/- |

| Cost of operation |

Rs.20 /h |

| General Information |

- The groundnut pods are shelled between the oscillating sector and the fixed perforated concave screen.

|

| Sailent Features |

- Clearance between the concave and oscillating sector is adjustable to suit the different varieties.

- Concave sieves are also replaceable depending upon pod size.

- The oscillating sector of the unit decorticates by rubbing action.

- The efficiency of the unit is 92%.

|

|

3.Groundnut Decorticator (Hand Operated)

| Function |

To shell groundnut pods and separate kernels |

| Specification |

Overall dimension

(L x B x H, mm)

|

600 x 350 x 700 |

| Capacity |

200 kg/h |

| Power required |

Manual |

| Cost of the unit (Approximate) |

Rs.9,000/- |

| Cost of operation |

Rs.5 /h |

| Sailent Features |

- Continuous horizontal type extrusion machine.

- Briquettes are formed by compression.

- Produces hollow briquettes with a calorific value of 3000 K.cal/kg.

|

|

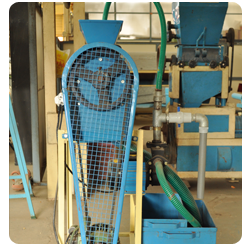

4.Sunflower Seed Sheller

| Function |

To shell the sunflower seeds and to separate husk |

| Specification |

Overall dimension

(L x B x H, mm)

|

1640 x 680 x 2830 |

| Capacity |

125 kg/h |

| Power required |

3 hp electric motor |

| Cost of the unit (Approximate) |

Rs.50,000/- |

| Cost of operation |

Rs.25 /h |

| General Information |

- It consists of a high speed rotor with six curved vanes with two flutes in each, a stator of a tapered wooden surface lined with a thick hard rubber, blower and a sieve assembly.

- The shelled material is subjected to an air blast in a chute and the husk is separated.

- The shelled kernels are separated in the sieve assembly

|

| Sailent Features |

- Power operated centrifugal type sheller.

- The Quality of oil and cake from shelled seeds is superior.

- Efficiency of the unit is 89%.

|

|

Agricultural Processing Equipments Study Content

5.Cotton Seed Delinting Machine

| Function |

To delint the fuzzy cotton seed for seed purpose |

| Specification |

Overall dimension

(L x B x H, mm)

|

660 x 490 x 1410 |

| Capacity |

50 kg/h |

| Power required |

1 hp electric motor |

| Cost of the unit (Approximate) |

Rs.30,000/- |

| Cost of operation |

Rs.15 /h |

| General Information |

- Five kg. of cotton seeds are fed into the stainless steel drum. The agitator is rotated.

- Half a litre of commercial sulphuric acid is poured slowly into the container having the cotton seeds through its periphery.

- Due to the churning action, the cotton fuzz is uniformly subjected to the acid reaction.

- At the end of 90 seconds, the acid treated seed and the slurry are washed with the water.

- The process of washing with water is repeated three to four times. Then, the seeds are collected and dried.

|

| Sailent Features |

- Batch type operation.

- Delinting of the seeds by acid.

- The efficiency of the unit is 95%.

- Seed born diseases are minimized.

- Acid treated seeds are free to flow.

|

|

6.Sorghum Pearler

| Function |

To remove the hull/seed coat from sorghum and other millets |

| Specification |

Overall dimension

(L x B x H, mm)

|

740 x 330 x 1140 |

| Capacity |

25 kg/h |

| Power required |

1 hp electric motor |

| Cost of the unit (Approximate) |

Rs.22,500/- |

| Cost of operation |

Rs.15 /h |

| General Information |

- This cycle of operation has to be repeated depending upon the extent of hull/seed coat to be removed.

|

| Sailent Features |

- Dry milling system to remove the seed coat.

- It has cylindrical abrasion disc type stones.

- Pearling efficiency is 80 – 85%

|

|

7.Hand Operated Thresher for Black Pepper

| Function |

To separate the pepper berries from the pepper vines |

| Specification |

Overall dimension

(L x B x H, mm)

|

500 x 500 x 1500 |

| Capacity |

60 kg/h |

| Power required |

Manually operated |

| Cost of the unit (Approximate) |

Rs. 7, 500/- |

| Cost of operation |

Rs.175/tonne of pepper |

| General Information |

- The unit has provision to adjust the clearance between the rotor and the concave to minimize damage to the berries.

- The empty spikes need to be fed second time for threshing depending on the berries present in the vines.

|

| Sailent Features |

- Suitable for threshing black pepper from the pepper vine.

- Efficiency – 96%.

- Suitable for small and marginal holdings.

|

|

8.Mechanical Thresher for Black Pepper

| Function |

To separate the pepper berries from the pepper vines |

| Specification |

Overall dimension

(L x B x H, mm)

|

750 x 600 x 500 |

| Capacity |

320 kg/h |

| Power required |

2 hp electric motor |

| Cost of the unit (Approximate) |

Rs.30,000/- |

| Cost of operation |

Rs.125/tonne of pepper |

| General Information |

- The clearance between the drum and rotor can be adjusted to minimize the breakage

|

| Sailent Features |

- Efficiency – 95%.

- Suitable for medium holdings

|

|

Agricultural Processing Equipments Study Content

9.Paddy Winnower

| Function |

Cleaning of paddy by winnowing |

| Specification |

Overall dimension

(L x B x H, mm)

|

1,210 mm x 960 mm x 1,430 mm |

| Type |

Power operated, continuous |

| Capacity |

7.5 q/h |

| Power required |

1 hp electric motor |

| Cost of equipment |

Rs. 7,000 |

| Winnowing efficiency |

97% |

| Labour requirement |

2 |

| Sailent Features |

- The machine winnows paddy already threshed by the paddy thresher or by other means.

- It has a feeding hopper at the top to receive the threshed paddy, chaff and straw bits.

- A blower provided at the bottom sends a stream of air which separates the straw, chaff and other impurities.

|

|

10.Maize Husker-cum-Sheller

| Function |

Dehusking and shelling of maize cobs |

| Specification |

Overall dimension

(L x B x H, mm)

|

2,450mm x 1,250mm x 1,500mm |

| Type |

Power operated, drum rotar type husker-cum-sheller |

| Capacity |

6.5 q (kernels)/h |

| Power required |

7.5 hp electric motor |

| Cost of equipment |

Rs 16,000 |

| Shelling efficiency |

98% |

| Labour requirement |

Seven |

| Sailent Features |

- The unit mainly consists of a hopper, a rotor, a sieve, a blower, auger and an elevator.

- Removal of sheath and shelling of cob takes place in rotor sieve assembly.

- Shelled kernels are carried by the auger to one end and then elevated and collected.

|

|

Agricultural Processing Equipments Study Content

| More Agriculture Engineering Study Material |

Open |

| More Agriculture Study Material |

Open |

| Premium Study Material & Test Series |

Open |